Explosion Testing for dust, gases & vapours

© March 2024

Powder volume resistivity

Determination of powder volume resistivity

This test determines powder volume resistivity by the simultaneous measurement of voltage and current passing through a test sample of known cross sectional area and depth. The test method is described in EN ISO/IEC 80079-20-2:2016 (Explosive atmospheres Part 20-2: Material characteristics - Combustible dusts test methods). An insulated measuring cell is used with two raised electrodes forming the sides. Material is poured into the cell and levelled across the electrodes with a straight edge. DC voltage is applied to the electrodes in the range 100 V to 1000 V and current flow is measured by a suitable ammeter. The test is repeated and the average measured current and applied voltage determined so that the electrical resistance across the electrodes may be calculated. The powder volume resistivity is derived from the average calculated resistance, height and length of the electrodes and space in between. Powder volume resistivity has units Ohm.m.

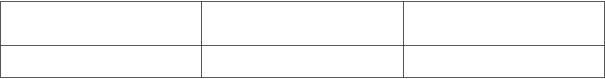

Powder volume resistivity test results table

Material

Relative Humidity

Resistivity

Sewage sludge

50%

1.7x10

14

Ohm.m

Explosion Testing

© March 2024