Explosion Testing for dust, gases & vapours

© March 2024

Minimum ignition temperature (MIT)

Minimum ignition temperature of a dust cloud

The minimum ignition temperature (MIT) is the lowest temperature of a hot surface that will cause a dust cloud, rather than a dust layer, to ignite and propagate flame. The test follows EN ISO/IEC 80079-20-2:2016 (Explosive atmospheres Part 20-2: Material characteristics - Combustible dusts test methods). Approximately 0.1 g of combustible dust is placed in a dust holder at the top of a temperature controlled furnace with an open bottom. The dust is dispersed by compressed air downwards past the hot surface of the furnace to see if ignition occurs and flames are produced. If the dust does not ignite, the furnace temperature is increased and the test repeated until ignition of the dust occurs. Once ignition has been established, the mass of the dust sample and injection pressure are varied to find the most vigorous explosive flame discharge. The temperature of the furnace is then reduced incrementally until flame propagation is no longer observed. At this temperature, the dust mass and injection pressure are varied to confirm that no ignition is found over ten consecutive tests. The minimum ignition temperature (MIT) is the lowest temperature of the furnace at which flame is observed minus 20 o C for furnace temperatures over 300 o C or minus 10 o C for furnace temperatures under 300 o C. For items of plant such as driers, testing the minimum ignition temperature is important to prevent a dust explosion occurring through contact with a hot surface. The internal temperature is generally limited to two thirds of the MIT when measured in degrees Centigrade. For example, a dust with a MIT of 450 o C would require a maximum operating temperature in the drying process of 300 o C, giving a safety margin of 150 o C.

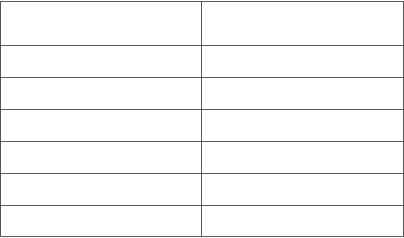

MIT test results table

Material

MIT

Grain dust

490

o

C

Coal dust

no ignition up to 850

o

C

Flour

400

o

C

Sugar

480

o

C

Aluminium dust

650

o

C

Sewage sludge

430

o

C

Explosion Testing

© March 2024

Minimum ignition

temperature (MIT)

Minimum ignition

temperature of a dust cloud

The minimum ignition temperature (MIT) is the lowest temperature of a hot surface that will cause a dust cloud, rather than a dust layer, to ignite and propagate flame. The test follows EN ISO/IEC 80079-20-2:2016 (Explosive atmospheres Part 20- 2: Material characteristics - Combustible dusts test methods). Approximately 0.1 g of combustible dust is placed in a dust holder at the top of a temperature controlled furnace with an open bottom. The dust is dispersed by compressed air downwards past the hot surface of the furnace to see if ignition occurs and flames are produced. If the dust does not ignite, the furnace temperature is increased and the test repeated until ignition of the dust occurs. Once ignition has been established, the mass of the dust sample and injection pressure are varied to find the most vigorous explosive flame discharge. The temperature of the furnace is then reduced incrementally until flame propagation is no longer observed. At this temperature, the dust mass and injection pressure are varied to confirm that no ignition is found over ten consecutive tests. The minimum ignition temperature (MIT) is the lowest temperature of the furnace at which flame is observed minus 20 o C for furnace temperatures over 300 o C or minus 10 o C for furnace temperatures under 300 o C. For items of plant such as driers, testing the minimum ignition temperature is important to prevent a dust explosion occurring through contact with a hot surface. The internal temperature is generally limited to two thirds of the MIT when measured in degrees Centigrade. For example, a dust with a MIT of 450 o C would require a maximum operating temperature in the drying process of 300 o C, giving a safety margin of 150 o C.