Explosion Testing for dust, gases & vapours

© January 2026

Testing for minimum ignition energy (MIE)

Dusts sensitive to ignition by electrical spark

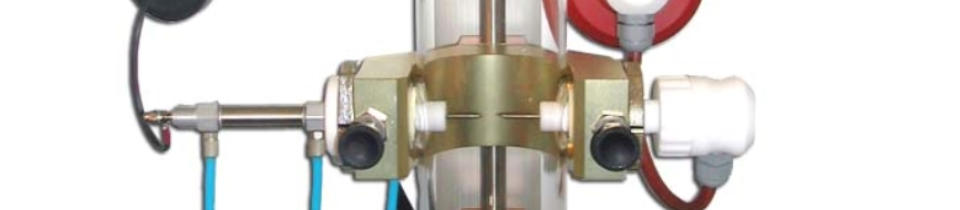

The minimum ignition energy (MIE) test measures the ease of ignition of a dust cloud by electrical and electrostatic discharges. The test is carried out according to EN ISO/IEC 80079-20-2:2016 (Explosive atmospheres Part 20-2: Material characteristics - Combustible dusts test methods). The MIE apparatus consists of a borosilicate tube placed over a dispersion cup and fitted with two electrodes. The electrodes are connected to a circuit that produces an electrical spark of known energy. A weighed sample of combustible dust is placed in the dispersion cup, which is blown up through the tube with compressed air past the ignition source. If flame propagation is observed, the energy of the spark is reduced until no flame propagation is seen for 10 consecutive tests. At that spark energy, a range of dust sample weights is tried to thoroughly investigate potential dust explosion concentrations. The test result is stated as an energy range, indicating that ignition took place at the higher value and no ignition took place at the lower value. The MIE is a measure of how sensitive an explosive dust cloud is to electrical spark ignition. Testing for minimum ignition energy gives guidance on whether ignition by electrostatic discharge from plant personnel or process conditions is likely to occur in practice.

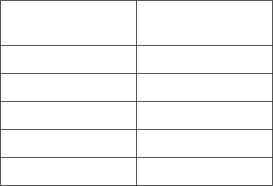

MIE test results table

Material

MIE

Coal dust

>1000mJ

Flour

300-1000mJ

Sugar

10-30mJ

Aluminium dust

100-300mJ

Sewage sludge

30-100mJ

- Classification test

- Explosion indices test

- 1m3 explosion test

- Minimum ignition energy

- Minimum ignition temperature

- Layer ignition temperature

- Limiting oxygen concentration

- Lower explosible limit

- Isothermal basket test

- Powder volume resistivity

- Train fire

- Thermal screen

- Air Over Layer

- UN Classification testing

Explosion Testing

© January 2026