Explosion Testing for dust, gases & vapours

© March 2024

Layer ignition temperature (LIT)

5mm layer ignition temperature test

The layer ignition test (LIT) test determines the lowest temperature at which a layer of dust of specific thickness, usually 5mm, ignites on a heated surface. It is an important test for industrial premises where heat generating equipment is present - such as electric motors or light fittings - as it evaluates the maximum permissible surface temperature to prevent fires and smouldering material. Testing is carried out according to The test follows EN ISO/IEC 80079-20-2:2016 (Explosive atmospheres Part 20-2: Material characteristics - Combustible dusts test methods). A layer of combustible dust of known thickness is created by placing two semicircular formers on the hotplate apparatus, filling them with the test sample and removing any excess above the formers. A thermocouple positioned on top of the layer monitors the dust temperature during the test and the temperature is continuously recorded using data logging equipment. Tests are repeated with fresh layers of dust until a minimum ignition temperature has been found. This is the lowest temperature, rounded down to the nearest integral multiple of 10 o C, at which ignition occurs in a layer of given thickness. The highest value at which ignition does not occur is also recorded. The latter temperature must be no more than 10 o C lower than the minimum ignition temperature recorded and is confirmed by at least three tests. Ignition is considered to have occurred if glowing or flaming is initiated in the material, or a temperature of 450 o C or more, or a temperature rise of 250 o C or more above the temperature of the hot surface, is measured in the test. Under the test standard, testing is discontinued if ignition of a dust layer does not occur below a heated surface temperature of 400 o C. This fact will be reported as the result of the test. Any thickness of dust layer may be investigated, but 5mm is generally regarded as representing the thickest layer of dust likely in a factory having fully enclosed plant and process operations allied to a good standard of housekeeping. Where there is the possibility that dust layers in excess of 5 mm may be formed, the maximum permissible surface temperature must be reduced. By testing the layer ignition temperature, fires caused by hot surfaces may be avoided. The temperature of motor casings, light fittings etc can be limited to less than the layer ignition temperature (LIT) with a suitable safety margin - usually 75 o C.

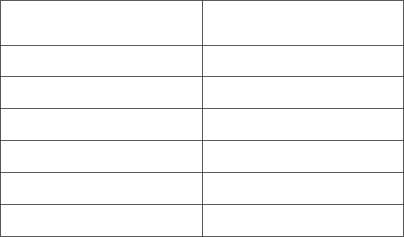

LIT test results table

Material

LIT

Grain dust

300

o

C

Coal dust

380

o

C

Flour

400

o

C

Sugar

450

o

C

Aluminium dust

430

o

C

Sewage sludge

250

o

C

Explosion Testing

© March 2024