Explosion Testing for dust, gases & vapours

© March 2024

Dust testing

Laboratory testing for dust explosion hazard

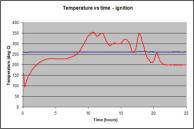

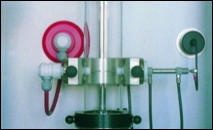

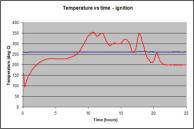

We are a UK based company specialising in laboratory testing of dusts and powders for explosion hazard. DSEAR (UK) & ATEX (Europe) are applicable for any potentially explosive substance that is found in the workplace. If the explosion hazard of the material is unknown, the classification test provides a simple means of screening to establish whether a dust is explosible or not. Classification Test Group A : Combustible dust which ignites and propagates flame. The dust is an explosion hazard and appropriate prevention and protection measures are necessary to meet mandatory safety legislation. Group B : Non-combustible dust which does not ignite. The dust is not an explosion hazard and no additional precautions are needed. If the dust is classified as explosible, further laboratory tests are required to provide information on the explosion and ignition characteristics of the material to show compliance with the essential safety requirements of ATEX or DSEAR. Layer Ignition Temperature This laboratory test determines the lowest temperature at which a layer of dust of specific thickness (usually 5mm) ignites on a heated surface. By limiting the temperature of any surface inside the company workplace, fires caused by motors and electric light fittings for example can be avoided. Minimum Ignition Temperature The minimum ignition temperature is the lowest temperature of a hot surface that will cause a dust cloud to ignite and propagate flame. Minimum Ignition Energy The minimum ignition energy is a measure of how sensitive a combustible dust is to electrical or electrostatic ignition. It gives guidance on whether ignition by electrostatic discharge from plant personnel or process conditions is likely to occur in practice. Explosion Indices This laboratory test measures the maximum explosion pressure and rate of pressure rise. These parameters are commonly used to design explosion protection systems – explosion venting, explosion suppression and explosion containment. Minimum Explosible Concentration This is the lowest concentration of dust that will support combustion. It may be used as an explosion prevention measure in areas where the concentration of the dust can be reliably controlled. Limiting Oxygen Concentration LOC is the highest concentration of oxygen that prevents a combustible dust forming an explosive atmosphere. This test is mandatory for any company relying upon inert gas as the basis for explosion safety. Isothermal Basket tests for self heating Self heating tests are based on measuring the self ignition temperatures of differently sized laboratory scale dust deposits with sufficient accuracy to allow scale up much larger industrial applications. Also known as hot storage tests, stainless steel mesh baskets are filled with sample and place in air circulating ovens at elevated temperature. Thermocouples monitor the core and oven temperature, with the purpose of finding the critical temperature at which self ignition first occurs. By plotting the volume to surface area ratio of differently sized samples together with the associated self ignition temperature, the graphical result may be extrapolated to much larger volumes and sizes. Powder Volume Resistivity Powder volume resistivity is determined by the simultaneously measuring the voltage and current passing through a dust sample of known cross sectional area and depth under laboratory conditions. Train Firing The train fire test measures the ability of a combustible dust layer to propagate flame in order that companies can safely transport, store and handle the material.

Explosion Testing

© March 2024

Dust testing

Laboratory testing for dust

explosion hazard

We are a UK based company specialising in laboratory testing of dusts and powders for explosion hazard. DSEAR (UK) & ATEX (Europe) are applicable for any potentially explosive substance that is found in the workplace. If the explosion hazard of the material is unknown, the classification test provides a simple means of screening to establish whether a dust is explosible or not. Classification Test Group A : Combustible dust which ignites and propagates flame. The dust is an explosion hazard and appropriate prevention and protection measures are necessary to meet mandatory safety legislation. Group B : Non-combustible dust which does not ignite. The dust is not an explosion hazard and no additional precautions are needed. If the dust is classified as explosible, further laboratory tests are required to provide information on the explosion and ignition characteristics of the material to show compliance with the essential safety requirements of ATEX or DSEAR. Layer Ignition Temperature This laboratory test determines the lowest temperature at which a layer of dust of specific thickness (usually 5mm) ignites on a heated surface. By limiting the temperature of any surface inside the company workplace, fires caused by motors and electric light fittings for example can be avoided. Minimum Ignition Temperature The minimum ignition temperature is the lowest temperature of a hot surface that will cause a dust cloud to ignite and propagate flame. Minimum Ignition Energy The minimum ignition energy is a measure of how sensitive a combustible dust is to electrical or electrostatic ignition. It gives guidance on whether ignition by electrostatic discharge from plant personnel or process conditions is likely to occur in practice. Explosion Indices This laboratory test measures the maximum explosion pressure and rate of pressure rise. These parameters are commonly used to design explosion protection systems – explosion venting, explosion suppression and explosion containment. Minimum Explosible Concentration This is the lowest concentration of dust that will support combustion. It may be used as an explosion prevention measure in areas where the concentration of the dust can be reliably controlled. Limiting Oxygen Concentration LOC is the highest concentration of oxygen that prevents a combustible dust forming an explosive atmosphere. This test is mandatory for any company relying upon inert gas as the basis for explosion safety. Isothermal Basket tests for self heating Self heating tests are based on measuring the self ignition temperatures of differently sized laboratory scale dust deposits with sufficient accuracy to allow scale up much larger industrial applications. Also known as hot storage tests, stainless steel mesh baskets are filled with sample and place in air circulating ovens at elevated temperature. Thermocouples monitor the core and oven temperature, with the purpose of finding the critical temperature at which self ignition first occurs. By plotting the volume to surface area ratio of differently sized samples together with the associated self ignition temperature, the graphical result may be extrapolated to much larger volumes and sizes. Powder Volume Resistivity Powder volume resistivity is determined by the simultaneously measuring the voltage and current passing through a dust sample of known cross sectional area and depth under laboratory conditions. Train Firing The train fire test measures the ability of a combustible dust layer to propagate flame in order that companies can safely transport, store and handle the material.